MBG Testing Update:

The MBG division has completed tests showing that their ANSI/NAAMM MBG treads meet the loading requirements of OSHA 29CFR 1910.24 (c). Treads tested included steel and aluminum treads with serrated or non-serrated edges in a range of lengths. The test included verification the treads meet the strength requirements of the latest version of the IBC as well as MBG's on strength requirements. Test Details.

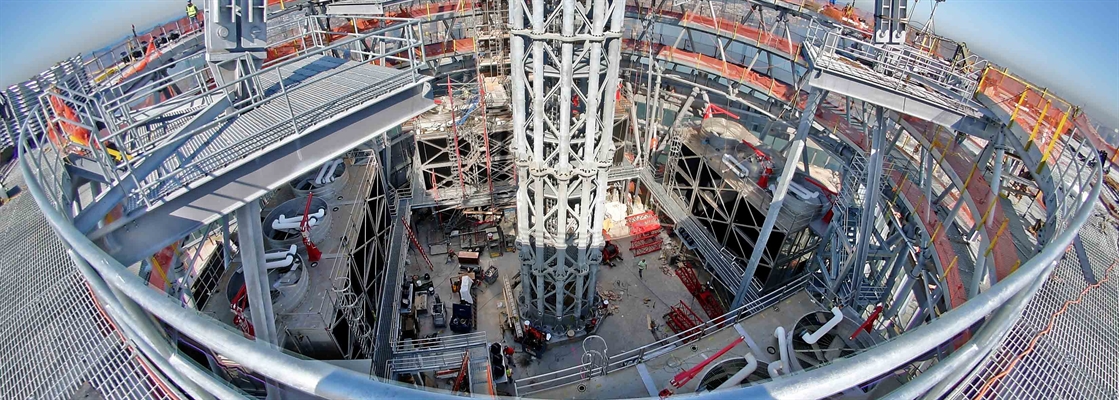

Today's Challenge

Specify the single most functional product for flooring, security, OEM, or general industrial applications from the myriad of products available.

Considerations

- Appropriate Materials

- Product Flexibility

- Product Life-Cycle

- Economy

- Maintenance

- Availability

Options

Consult with manufacturers of a single product that may be appropriate for your application. Select from a wide range of products which are available nationwide and manufactured to international standards.

Why Metal Bar Grating?

Appropriate Materials

Grating manufactured from carbon steel, aluminum, stainless steel, and special alloys provides safe, functional, durable products for all environments.

Product Flexibility

Metal bar grating can be fabricated to suit any configuration for your specific application. Bar spacing and riveted centers are variable and allow for products with open areas ranging from 50% to 90%. Extensive open areas allow for the passage of light and air, reducing the need for additional lighting and ventilation. Metal bar grating can support loads ranging from light pedestrian traffic, to the heaviest vehicular and aircraft weight.

Product Life-Cycle

Designed for strength and longevity, metal bar grating outlasts wood, plastic, and competing metal products. Metal grating products are manufactured from 100% recyclable materials.

Economy

Prefabricated and ready for installation, bar grating reduces the need for costly field labor. The economies of bar grating are such that these products dominate their field.

Maintenance Free

The high percentage of open area allows for excellent drainage and the free passing of debris, creating a virtually maintenance-free product.

The NAAMM Advantage

The Metal Bar Grating Division is comprised of members from the United States, Canada, Mexico, and South America. The Division publishes the only manuals for standard and heavy-duty bar grating which are recognized and approved by the American National Standards Institute. These NAAMM/ANSI standards are your guide to assuring that your grating needs are satisfied by products of consistent quality and availability. This, in addition to the lowest total cost, makes metal bar grating the superior solution.

Technical Publications

Sort

-

Metal Bar Grating Code of Standard Practice

- 2025

- MBG 535-25

-

Metal Bar Grating Engineering Design Manual

- 2024

- MBG 534-24

-

Metal Bar Grating Manual 531-24

- 2024

- MBG 531-24

Technical data, specifications, and recommended practices applicable to steel, stainless steel and aluminum gratings; includes photographs, load tables and details of typical installations. (ANSI/NAAMM MBG 531-24)

-

Heavy Duty Metal Bar Grating Manual

- 2024

- MBG 532-24

Essential current technical data concerning heavy duty bar gratings of structural carbon steel and stainless steel. Includes information on types of gratings, fabrication, dimensional standards, load tables, installation and guide specifications. (ANSI/NAAMM MBG 532-24)

-

Welding Standards for Fabrication of Steel, Stainless Steel and Aluminum Bar Grating

- 2021

- MBG 533-21

MBG members

To obtain more information on ordering or specifying Metal Bar Grating, click on the individual members listed below: